The use of industrial high performance Sealants, Adhesives, Foams and Encapsulants has seen tremendous growth in the past decade. Silicone, Epoxy, Polyurethane and Methacrylate thermosetting materials, give manufacturers the high performance, and competitive edge they need. Seamless automation flow, analytical attention to waste reduction, and planned down times, enable a much clearer in-site into the overall stability and sustainability of the ROI. Let us show you how to increase your production rates, and decrease your production costs, by helping you put exactly the right amount of material, exactly where you want it, every time!

|

Compact PR70 Series Meter Mix Dispense machines for processing a wide range of 2 component polyurethanes, silicones and epoxies. Ratio accuracy to ±1%. The PR70-V upgrades the fixed to a variable ratio to accommodate volumetric ratios of 1: 1 to 24:1). Designed to accurately meter, mix and dispense medium-to-low viscosity materials for potting, gasketing, sealing, encapsulation and syringe filling. All the features you need, in a compact, modular design. Sales Brochure

|

|

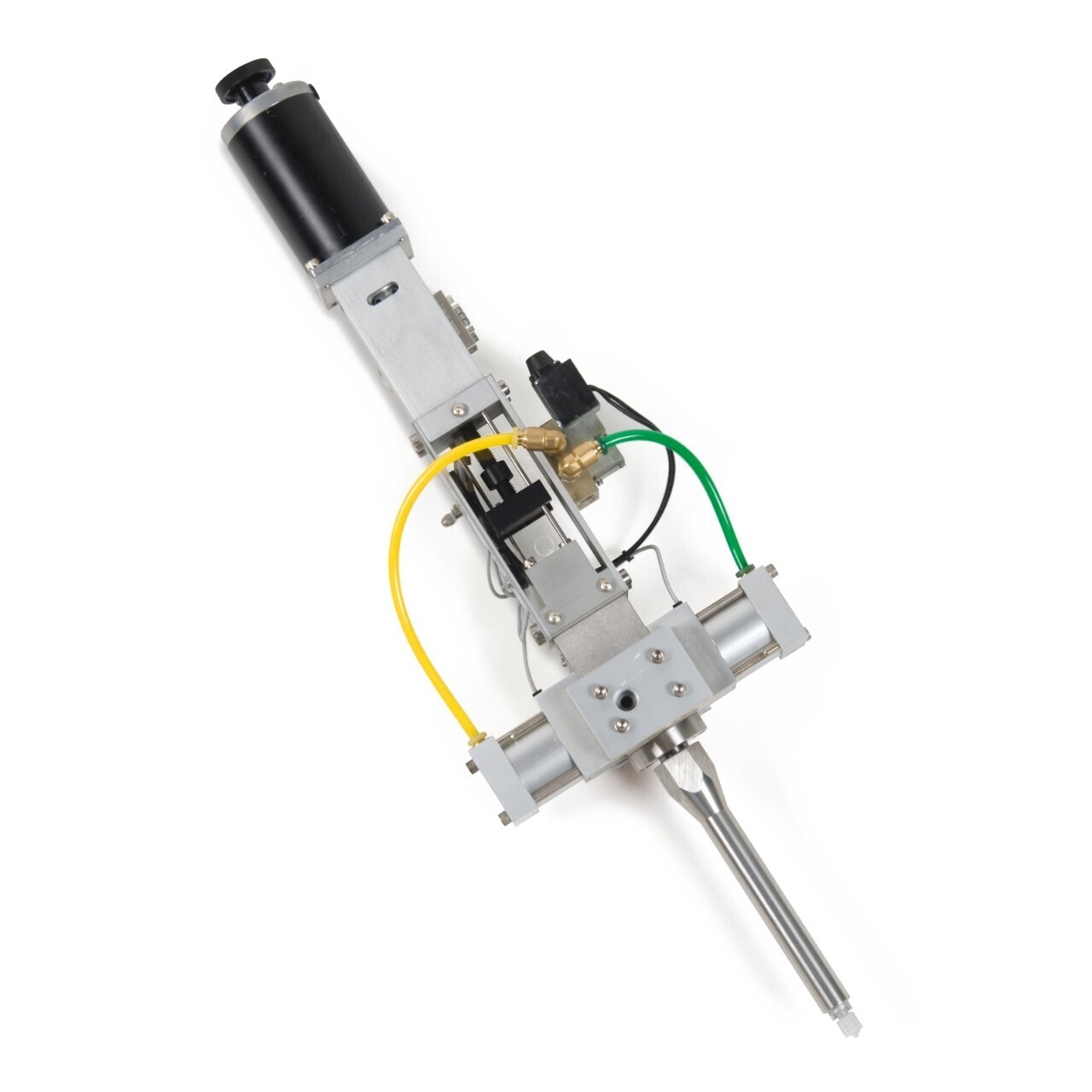

EFR Electric Fixed Ratio for Complete 2K Material Control. The EFR provides advanced material control in applications requiring consistent shots and beads. Provides highly accurate, even with low flow rates. Capable of shots, beads and continuous flow dispense with superior repeatability. Meter Mix Dispense a wide range of two component materials. The EFR is easy to configure, operate and maintain.

The electric motor directly controls the movement in the pumps so that the requested flow rate is achieved directly from the start. With the additional automatic calibration cycle, snake heads at the start and end are eliminated. The EFR gives you the versatility to choose the material and flow rates you need no matter your project requirements. While the motor is powerful enough to give you a high output up to 3.2L per minute, the precise encoder helps you control the flow to reach very low flows or small shots consistently. |

|

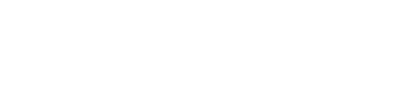

Two Component viscous adhesive pail extruder for 1:1 by volume ratio materials. For high viscosity materials (30,000 - 1,000,000cps), material must be supplied in 20L (5 Gallon) pails. Pump is severe duty construction suitable for abrasively filled materials. The 1:1 Extruder is both a meter and pump in one, designed to meter directly from shipping pails, no pre-feed equipment required. System features:

|

|

ExactaBlend AGP (Advanced Glazing Proportioner) for Two Part Structural Sealants provides on-ratio dispensing of 2 component sealants and adhesives for curtainwall, insulating glass and other applications. The variable ratio ExactaBlend AGP offers advanced technologies at an affordable price.

Real-time ratio assurance means less waste, more profits The ExactaBlend AGP provides accurate, on-ratio mixing and a consistent flow rate, even during pump changeover. The system monitors the flow rate of the base material and automatically adjusts the catalyst flow rate to achieve an on-ratio dispense. It also provides automatic shut-down if off-ratio conditions occur. Material waste is reduced, and with the optimal mix quality, you can expect even material curing, without soft spots. When the ExactaBlend AGP is coupled with the MD2 Valve, the catalyst and base materials are blended together in the mixer – apart from the applicator. This reduces the amount of base purge material needed to clean the mixer. |

|

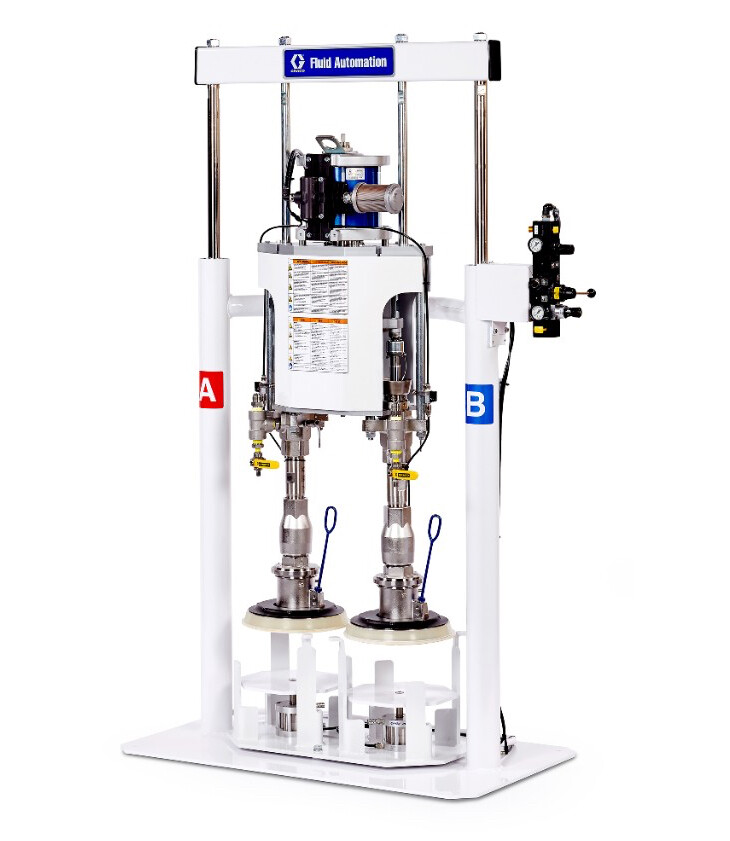

PR-X (EOAT) Meter, Mix and Dispense End Of Arm Tool system for two component robotically applied applications. True first-in-first-out fluid path design helps eliminate material clogging and separation when dispensing material with high density and viscosity.

Choose from a wide range of container feed sizes from cartridges to drums.

|

|

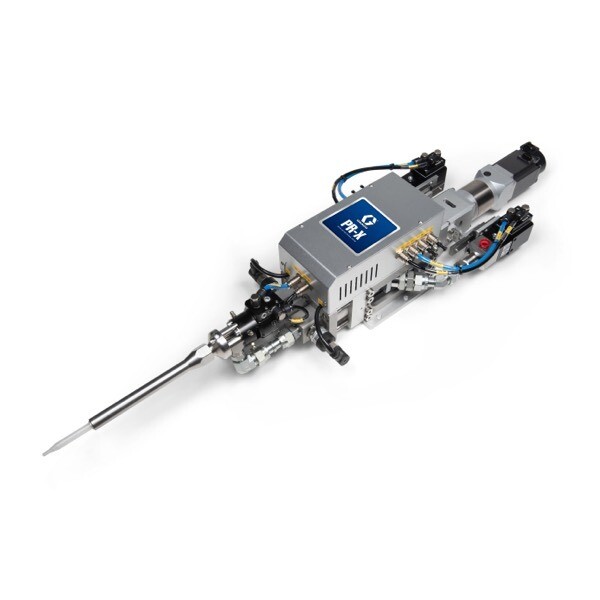

The TS8200D Series Micro-Meter Mix is a precision volumetric mixing and dispensing system for 2-component material. It consists of 2 progressive cavity pumps integrated in a fluid manifold connected to the static mixing nozzle. Part A and part B of the material is precisely fed by the progressive cavity pump with the correct ratio into the static mixing nozzle to provide accurate mixing and dispensing output.

Every component of the pump was designed to the highest tolerances and manufactured to the strictest degree of precision, ensuring world class accuracy and repeatability. TS580D-MM smart controller features an intuitive touchscreen user-interface for easy setup and operation. Pump calibration is quick and easy. Dispensing parameters can be quickly dialed in on the touchscreen. TS580D-MM smart controller features an intuitive touchscreen user-interface for easy setup and operation. Pump calibration is quick and easy. Dispensing parameters can be quickly dialed in on the touchscreen. |

|

PosiDot PD44 Micro shot Meter Mix Dispense Valve is specifically designed to dispense small amounts of water thin to paste viscosity materials from 0.005 cc's to 5 cc's. This highly precise rod style positive displacement metering valve provides extremely repeatable shot and ratio accuracy for applications requiring finite and fractional deposits of mixed material. Suitable for two component epoxies, polyurethanes, silicones, and methacrylates. Uses disposable static mixers.

|

|

The Voltex Dynamic Mix Valve is a rotary static valve that consistently mixes and dispenses materials requiring exceptional mixing energy. Engineered with rugged components and precision controls that eliminate dispensing inconsistencies, reduce maintenance downtime, and optimize material usage. Reliably mixes and dispenses difficult foaming polyurethanes, low viscosity silicones, and other hard to blend two component chemistries.

|

|

High Output HFR Hydraulic Fixed Ratio Meter Mix Dispense machine delivers high flow rates of high viscosity 2 part silicones, polyurethanes, and epoxies. Fed directly from drum transfer or extrusion ram pumps. The HFR is a popular choice in the Solar, Wind Power, Insulated Glass , Automotive, Polyurethane Foam, and Packaging industries. With its accuracy and repeatability, the Graco HFR lets you hit a specific ratio and volume - the first time, and every time.

|

|

The E-Flo iQ Metering & Dispensing System for single component sealants and adhesives. This dispensing solution was designed to meter directly from the drum, making it an intelligent system that delivers sustained in-plant performance, minimizes maintenance costs and reduces system complexity. Sales Brochure

|

|

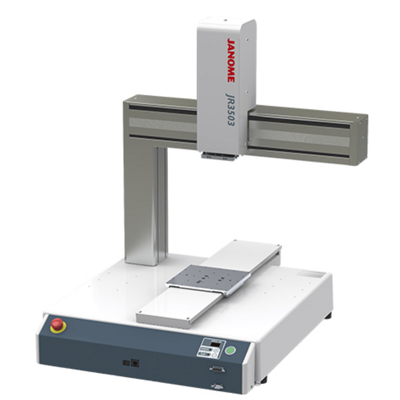

UniXact Fully Integrated X Y Z Dispense Platform ideal for automated bonding, sealing and potting applications from prototype development phase to mass production. The 500 x 500mm workspace can be configured with part fixturing or y slides. A variety of dispense valves are available to meet your application and material requirements.

|